Power Petrol

Gas Station Equipment

Gas Station Equipment

The system has many international and local approvals – UL, EN, IP, Kiwa etc. – and is already used and approved major international petroleum companies, in response to whose needs it has been conceived, developed and successfully launched into the market.

All products are available in a wide variety of sizes and configurations making the system suitable to various kinds of installation.

All SMARTFLEX primary piping consists of a multi-layer composite wall lined product pipe that combines the excellent mechanical properties of HDPE with the low permeability and high resistance to hydro-carbons of a new class of polymers used in the lining material and creates a level of hydro-carbon compatibility unattainable other fuel pipes available on the market today.

The most common applications for SMARTFLEX pipes and fittings, both in suction and pressure installations, are as follows:

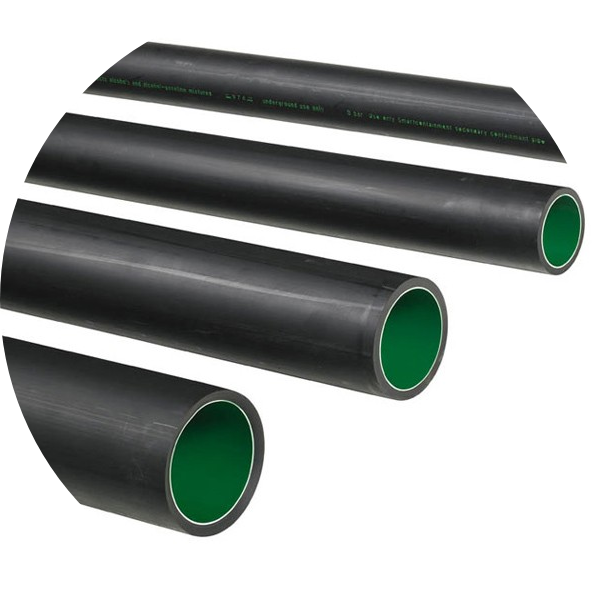

SMARTFLEX has a vast range of pipes and fittings including: Single-wall lined pipes for both product lines and vent/vapor and filling lines.

SMARTFLEX has a vast range of pipes and fittings including: Double-wall lined pipes for more demanding containment and monitoring requirements.

A full range of electro-fusion fittings for safe, corrosion-proof joints. Spigot and riser fittings. Mechanical fittings. Flexible and electro-fusion entry boots for positive sealing of sumps. Leak monitoring systems HDPE tank sumps and dispenser sumps. Welding units and tooling.

Single and double wall configuration

Complete range of electro-fusion single wall and double wall fittings, mechanical, spigot and transition fittings. Complete range of entry and terminating boots

Real time monitoring and containment

High impact resistance.

Excellent resistance to corrosion.

Excellent chemical resistance to hydrocarbons, saline, acid and alkaline solutions and environments

Outstanding long-term resistance to pressure

Barcode technology for ease and accuracy of welding during installation allowing for full traceability

Comprehensive range of assembly tools and equipment